NBR 70

• Nitril rubber

• Hardness: approx. 70 ShA

• Colour: black

• Temperature-resistant to +100℃

• High friction coefficient, low wear, good resistance to oils, greases, ozone, low bending resistance, antistatic

NR

• Natural rubber

• Hardnesses: 40 ShA, 50 ShA

• Colours: white, red, maroon

• Temperature-resistant to +60℃

• Extremely high friction coefficient, highly elastic, low tear propagation resistance

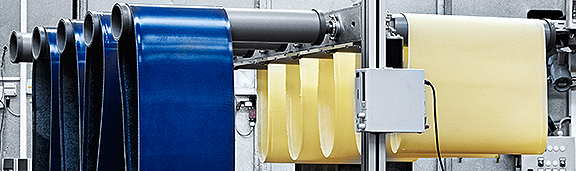

NBR

• Nitrile rubber

• Hardnesses: 65 ShA, 75 ShA

• Colours: white, blue, light grey

• Temperature-resistant to +80℃

• Wear-resistant, FDA approved (white only), very good resistance to oils and greases

xNBR

• Carboxylated nitrile rubber

• Hardness: 75 ShA

• Colours: pale beige

• Temperature-resistant to +100℃

• Very wear-resistant, suitable for accumulation operation, extremely good resistance to oils and greases

EPDM

• EPDM rubber

• Hardness: 65 ShA

• Colours: green

• Temperature-resistant to +120℃

• Very good resistance to ozone, acids and alkalis, high friction coefficient