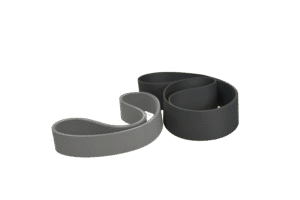

Drive and conveyor belts

Endless Possibilities on the Move

The literally endless Esband drive and conveyor belts have neither seams nor joints. This makes them ideal for a wide range of applications in machinery and plant engineering.

Customized solutions…

For every machine, drive type, and transported material, we develop an individual solution. We combine different carrier materials, coatings, and refinements to create tailor-made endless solutions for our customers.

…produced just for you!

Our specialized mechanical engineering ensures continuous innovation and rapid adaptability. This allows our production to meet customer requirements in the best possible way.

In our in-house knitting facility, endless knitted fabrics are produced to order. These are then finished with various coatings. A wide range of special processing options completes our portfolio.