What service lives are possible with ESBAND drive belts or conveyor belts?

The service life of flat belts depends on a number of influencing factors (including belt speed, pulley diameters, chemical stress or the type of clamping fixture). Unlike with positive-fit transfer elements, it is therefore not possible to calculate a generally applicable service life for flat belts. Rather, it must be determined on the basis of tests under later actual conditions.

What information does ESBAND require to be able to calculate for a drive belt to be used in my particular application?

The motor data, details of the pulley diameters and information about the type of pretensioning are crucial to the drive belt calculations. However, the more data we have relating to the desired belt, the faster we can do the calculations to find the right belt.

We recommend that you fill in the online form so as to ensure that no data is accidentally forgotten.

What information does ESBAND require in order to come up with a suitable conveyor belt for my particular application?

The design of a conveyor belt can’t be calculated. Rather, it is derived from the type of use. Consequently, the desired properties of the belt and the required resistances are crucial to the choice of belt. Of course, it is also important to specify the dimensions.

We always recommend that you fill in the online form. When you do that, it is also possible to upload an application diagram.

Why is there a minimum quantity?

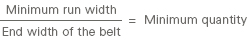

An ESBAND always comes from a complete production run. The belts are not cut out from this run until the end of the production process. Given that the production runs have been specially made to meet the customer’s requirements, the entire run must also be bought.

For production-related reasons, there is a minimum run width of 420 mm in the case of NE runs. This is 300 mm in the case of the remaining coating materials.

Why is there a surplus/shortfall in my orders?

An ESBAND always comes from a production run. These runs are coated manually, which means that there may be irregularities in the edge area especially. For that reason, we manufacture our runs somewhat wider so that the desired number of perfect belts can then be cut out. However, this can result in quantities that deviate somewhat.

According to our Terms and Conditions,such surpluses/shortfalls of up to +/- 10% of the desired quantity are permitted and must be accepted by the customer.

How great are the length and width tolerances for ESBAND drive belts and conveyor belts?

The standard length tolerances for our belts is +/- 0.5%. In the case of belts with Kevlar fabric it is +/- 1.0%. For elastic belts, the tolerance increases to +/- 2.0%.

The width tolerance up to a belt width of 50 mm is +/- 0.5 mm.

The tolerance ranges can normally be narrowed or shifted. If you have any questions about this, we are of course at your disposal at any time.

What tolerances apply to garniture tapes?

For Details about the different tolerances of garniture tapes kindly contact our sales department.

What tolerances apply to suction tapes?

Different tolerances apply to suction tapes, depending on the material.

For more information please contact our sales department.

For how long can garniture tapes and suction tapes be stored?

Our sales department is happy to provide you with all information regarding the storage of garniture and suction tapes.

Are there special storage regulations for garniture tapes and suction tapes?

To get more information about special storage regulations please contact our sales department.