The endless Schlatterer belt – An original that will impress you!

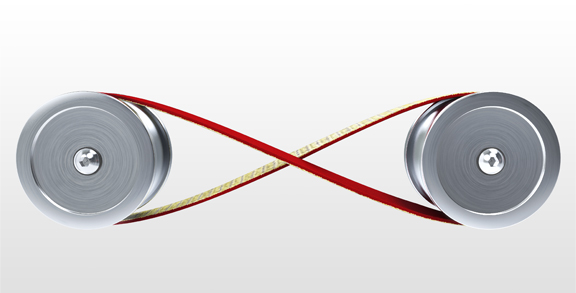

The endless Schlatterer belt (short: Esband) has stood for quality, innovation, and precise craftsmanship for decades. Through a unique manufacturing process, a true endless belt is created without any joints.

Research and development, constant innovation and quality assurance are our top priority. But that’s not the only reason why Esband represents a revolution in terms of drive belts, conveyor belts, garniture tapes and suction tapes. It’s endless production without its weakest link: The seam. Thanks to absolute homogeneity, they guarantee excellent running properties and a long service life. A wide range of different base materials and coatings offer every user the Esband that’s tailored to their needs – thanks too to our own mechanical engineering.

Advantages

Only belts and tapes manufactured using the genuine endless method carry our brand name “Esband”. Manufactured free of seams, they bring you numerous advantages:

Quality assurance

At Schlatterer, quality assurance has never been an unfamiliar concept. It covers a multitude of individual tests and inspections, from the raw material to the final inspection. Only then is an Esband delivered. Specially tailored to the applications profile of our customers, in addition we test other product properties and develop meaningful testing processes for them. Besides mechanical and physical quality requirements, in many areas an Esband is subject to the strict guidelines of the foodstuffs industry and is approved for use in tobacco processing.

At Schlatterer, quality assurance also means that used or worn conveyors and belts can be sent back to us and examined in our laboratories. The analysis data is immediately incorporated into the development and optimisation of Schlatterer products.

Made in Germany

The “Made in Germany” label is an expression of the highest quality ans reliability. Max Schlatterer GmbH & Co. KG products are, without exception, “Made in Germany” and have made the company what it is today: A global market leader that stands out by virtue of innovation, product quality, economy, reliable delivery and closeness to the customer.